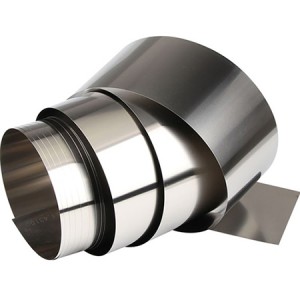

ERNiCrMo-3 Welding Waya Inconel 625 Welding Waya

ErNiCrMo-3 (Inconel 625 UNSNO6625)Welding Waya

♦ Weliding Waya Name: ErNiCrMo-3, Inconel 625 TIG / MIG Waya

♦ MOQ:15kg

♦ Fọọmu: MIG(15kgs/spool), TIG(5kgs/apoti)

♦ Iwọn:Opin 0.01mm-8.0mm

♦ Iwọn to wọpọ:0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM / 3.8MM / 4.0MM / 5.0MM

♦ Awọn idiwọn:Ni ibamu si Ijẹrisi AWS A5.14 ASME SFA A5.14

ErNiCrMo-3lo fun alurinmorin 625 (N06625) alloy, 20 alloy, 825,25-6Mo, 9% Ni irin tabi awọn miiran molybdenum irin, tun lo fun alurinmorin ti o yatọ si ohun elo ati ki ipata sooro surfacing ti awọn ohun elo dada.

O tayọ darí-ini ni ga ati kekere awọn iwọn otutu.Resistance to lagbara ipata, wahala ipata kiraki, pitting ati backback ipata ni kan jakejado ibiti o ti ifoyina ati idinku media.

| C | Al | Si | Mn | Cr | Ni | Ti | Fe | S | Cu | Mo | P | Nb + Ta | Awọn miiran |

| ≤0.10 | ≤0.40 | ≤0.50 | ≤0.50 | 20.0 - 23.0 | ≥58.0 | ≤0.40 | ≤5.0 | ≤0.015 | ≤0.50 | 8.0 - 10.0 | ≤0.02 | 3.15 – 4.15 | ≤0.50 |

| Iwọn opin | Ilana | Folti | Amps | Gaasi Idaabobo | |

| In | mm | ||||

| 0.035 | 0.9 | GMAW | 26-29 | 150-190 | Sokiri Gbigbe100% Argon |

| 0.045 | 1.2 | 28-32 | 180-220 | ||

| 1/16 | 1.6 | 29-33 | 200-250 | ||

| 1/16 | 1.6 | GTAW | 14-18 | 90-130 | 100% Argon |

| 3/32 | 2.4 | 15-20 | 120-175 | ||

| 1/8 | 3.2 | 15-20 | 150-220 | ||

| Ipo | Agbara Fifẹ MPa (ksi) | Agbara ikore MPa (ksi) | Ilọsiwaju% |

| AWS atunṣe | 760(110) | Lai so ni pato | Lai so ni pato |

| Aṣoju esi bi welded | 790(115) | 590(85) | 35 |

Kini idi ti ERNiCrMo-3?

Akoonu irin kekere, o le ṣee lo ni alurinmorin ti nickel-chromium molybdenum alloy,

O le ṣee lo fun cladding ati alurinmorin ti o yatọ si ipilẹ awọn irin gẹgẹbi Ni-Cr-Mo alloy pẹlu irin alagbara, irin ati erogba, irin.

O ni o ni o dara ifoyina resistance ati atehinwa ayika.

Awọn akoonu giga ti molybdenum n pese aapọn ti o dara ati resistance si pitting ati creviceipata.

Aaye ohun elo ERNiCrMo-3:

O dara fun alurinmorin ti nickel-chrome-molybdenum alloy, gẹgẹ bi awọn Inconel625, Incoy 825, ati ki o tun le ṣee lo fun alurinmorin ati surfacing ti nickel-base alloy ati alagbara, irin dissimilar ohun elo.O le ṣee lo ni ayika lati iwọn kekere si 540 ℃.