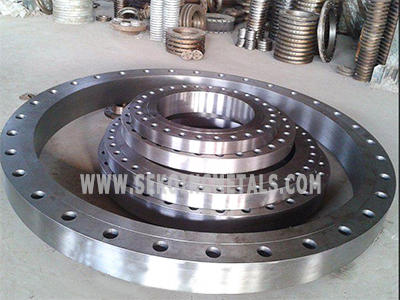

Incoloy 825 Flange

Incoloy 825 (W.Nr 2.4858) Flange

Ohun elo Flange :Incoloy Alloy 825 (UNS N08825)

Awọn oriṣi Flange:Ni ibamu si ibara awọn ibeere

Deeti ifijiṣẹ :15-30 ọjọ

Akoko Isanwo:T/T, L/C, Paypal, Ect

Sekoinc Awọn irin Awọn iṣelọpọ akọkọ ati pese awọn ohun elo Flanges pataki, a gba aṣẹ ayẹwo

Alloy 825ni Awọn akoonu nickel ti o ga julọ n fun alloy doko aapọn ipata idinku resistance.Idaabobo ipata dara ni ọpọlọpọ awọn media, gẹgẹbi imi-ọjọ, phosphoric, nitric ati Organic acids, awọn irin alkali gẹgẹbi sodium hydroxide, potasiomu hydroxide ati awọn ojutu hydrochloric acid.

Iṣe gbogbogbo ti o ga julọ ti Incoloy 825 ni a fihan ni itusilẹ ijona iparun kan pẹlu ọpọlọpọ awọn media ibajẹ, gẹgẹbi imi acid, acid nitric ati sodium hydroxide, gbogbo ni ilọsiwaju ni ohun elo kanna.

| Alloy | % | Ni | Cr | Mo | Fe | C | Mn | Si | S | Cu | Al | Ti | P |

| 825 | Min. | 38.0 | 19.5 | 2.5 | 22.0 | - | - | - | - | 1.5 | 0.6 | - | |

| O pọju. | 46.0 | 23.5 | 3.5 | - | 0.05 | 1.0 | 0.5 | 0.03 | 3.0 | 0.2 | 1.2 | 0.03 |

| iwuwo | 8.14 g/cm³ |

| Ojuami yo | 1370-1400 ℃ |

| Ipo | Agbara fifẹ Rm N/mm² | Agbara ikore Rp 0. 2N/mm² | Ilọsiwaju Bi% | Brinell líle HB |

| Itọju ojutu | 550 | 220 | 30 | ≤200 |

• Awọn oriṣi Flange:

→ Flange awo alurinmorin (PL) → Isokuso-lori Flange Ọrun (SO)

→ Flange ọrun alurinmorin (WN) → Flange Integral (IF)

→ Flange alurinmorin iho (SW) → Flange asapo (Th)

→ Flange apapọ lapped (LJF) → Flange afọju (awọn (BL)

♦ Awọn ohun elo Flange akọkọ A Ṣejade

• Irin ti ko njepata :ASTM A182

Ite F304/F304L, F316/ F316L,F310, F309, F317L,F321,F904L,F347

Irin Alagbara Duplex: Ite F44 / F45 / F51 / F53 / F55 / F61 / F60

• Awọn ohun elo Nickel: ASTM B472, ASTM B564, ASTM B160

Owo 400,Nickel 200, Incoloy 825, Incoly 926, Inconel 601, Inconel 718

Hastelloy C276, Alloy 31, Alloy 20, Inconel 625, Inconel 600

• Titanium Alloys:Gr1 / Gr2 / Gr3 /Gr4 / GR5/ Gr7 / Gr9 / Gr11 / Gr12

♦ Awọn idiwọn:

ANSI B16.5 Class150,300,600,900,1500(WN,SO,BL,TH,LJ,SW)

DIN2573,2572,2631,2576,2632,2633,2543,2634,2545(PL,SO,WN,BL,TH)

Incoloy 825 Awọn ọja to wa ni Awọn irin Sekonic

Kini idi ti Incoloy 825?

825 alloy jẹ iru ẹrọ alloy imọ-ẹrọ gbogbogbo, eyiti o ni acid ati alkali resistance resistance in oxidation and idinku ayika ati imunadoko ti o munadoko si idinku ipata wahala fun akopọ nickel ti o ga. acid, phosphoric acid, acid nitric ati Organic acid, si alkali, gẹgẹbi sodium hvdroxide, potasiomu hvdroxide ati ojutu hvdrochloric acid.Išẹ okeerẹ ti o ga julọ ti awọn ifihan alloy 825 ni itusilẹ sisun iparun ti ọpọlọpọ awọn alabọde ipata, gẹgẹbi sulfuric acid, acid nitric ati sodium hvdroxide ni gbogbo wọn mu ni ohun elo kanna.

•Ti o dara resistance to wahala ipata wo inu.

•Rere resistance to pitting ati crevice ipata

•Rere resistance to oxidization ati ti kii oxidizing acid.

•Awọn ohun-ini ẹrọ ti o dara ni iwọn otutu yara tabi to 550 ℃

•Iwe-ẹri ti ohun elo titẹ iṣelọpọ ti 450 ℃

Aaye ohun elo Incoloy 825:

•Awọn ohun elo bii awọn coils alapapo, awọn tanki, awọn apoti, awọn agbọn ati awọn ẹwọn ni awọn ohun ọgbin mimu sulfuric acid

•Awọn olupaṣiparọ ooru ti omi-omi okun, awọn ọna fifin ọja ti ita;tubes ati irinše ni ekan gaasi iṣẹ

•Awọn paarọ ooru, awọn evaporators, scrubbers, awọn paipu dip ati bẹbẹ lọ ni iṣelọpọ phosphoric acid

•Awọn olupaṣiparọ ooru ti afẹfẹ tutu ni awọn isọdọtun epo

•Onjẹ processing

•Ohun ọgbin kemikali