AMS ASME ASTM fun inconel625 alloy navigators

AMS ASME ASTM fun inconel625 awọn aṣawakiri alloy,

625 Alloy, Inconel 625 Ifi, Inconel 625 Rods, Inconel 625 dì, Inconel 625 awo, Inconel 625 strip,

Awọn orukọ Iṣowo ti o wọpọ: Inconel 625, UNS NO6625, Nickel Alloy 625, Alloy 625, Nickel 625, W.Nr.2.4856

Inconel Alloy 625 jẹ ti kii ṣe oofa, ipata ati sooro ifoyina, nickel-chromium alloy.Agbara giga ti Inconel 625 jẹ abajade ti apapo lile ti molybdenum ati niobium lori ipilẹ chromium nickel ti alloy.Inconel 625 ni resistance nla si ọpọlọpọ awọn agbegbe ipata ti ko ni ailẹgbẹ pẹlu awọn ipa iwọn otutu bii ifoyina ati carburization.Agbara iyalẹnu rẹ ati lile ni awọn sakani iwọn otutu lati awọn iwọn otutu cryogenic si iwọn otutu giga to 2000 ° F (1093° C) jẹ yo ni akọkọ lati awọn ipa ojutu ti o lagbara ti awọn irin refractory Columbium ati molybdenum ninu matrix nickel-chromium.

Inconel 625 Kemikali Tiwqn

| % | Ni | Cr | Fe | Mo | Nb+Ta | Co | C | Mn | Si | S | Al | Ti | P |

| Min. | 58.0 | 20.0 | - | 8.0 | 3.15 | - | - | - | - | - | - | - | - |

| O pọju. | - | 23.0 | 5.0 | 10.0 | 4.15 | 1.0 | 0.1 | 0.5 | 0.5 | 0.015 | 0.4 | 0.4 | 0.015 |

Inconel 625 ti ara Properties

| iwuwo | 8.4 g/cm³ |

| Ojuami yo | 1290-1350 ℃

|

Inconel 625 Aṣoju Mechanical Properties

| Ipo | Agbara fifẹ Rm N/mm² | Agbara ikore Rp 0. 2N/mm² | Ilọsiwaju Bi% | Brinell líle HB |

| Itọju ojutu | 827 | 414 | 30 | ≤220 |

Inconel 625 Awọn ajohunše ati Awọn pato

AMS 5599, AMS 5666, AMS 5837, ASME SB 443 Gr 1, ASME SB 446 Gr 1, ASTM B 443 Gr 1, ASTM B 446 Gr 1, EN 2.4856, ISO 15156-3, 073-NACE

UNS N06625, Werkstoff 2.4856

| Waya | Dìde | Sisọ | Rod | Paipu | |

| AMS 5599, AMS 5666, AMS 5837, AMS 5979, ASTM B443 | ASTM B443 | AMS 5599, AMS 5979, ASTM B443 | ASTM B 446 SAE/AMS 5666, VdTÜV 499 | Alailẹgbẹ Pipe | Weld Pipe |

| ASTM B 444/B 829 & ASME SB 444/SB 829SAE/AMS 5581 | ASTM B704/B751 ASME SB704/SB 751ASTM B705/B 775 , ASME SB 705/SB 775 | ||||

Inconel 625 Awọn ọja to wa ni Awọn irin Sekonic

Inconel 625 Ifi & Awọn ọpa

Awọn ọpa iyipo / Awọn ọpa alapin / Awọn ọpa hex, Iwọn Lati 8.0mm-320mm, Ti a lo fun awọn boluti, awọn fastners ati awọn ẹya miiran

Inconel 625 alurinmorin waya

Ipese ni alurinmorin waya ati orisun omi waya ni okun fọọmu ati ki o ge ipari.

Inconel 625 dì & awo

Awọn iwọn to 1500mm ati gigun to 6000mm, Sisanra lati 0.1mm si 100mm.

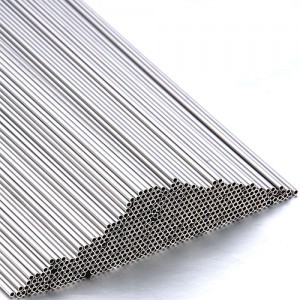

Inconel 625 tube ti ko ni itara & paipu Welded

Iwọn awọn iṣedede ati iwọn adani le jẹ iṣelọpọ nipasẹ wa pẹlu ifarada kekere

Inconel 625 rinhoho & okun

Ipo rirọ ati ipo lile pẹlu oju didan AB, iwọn to 1000mm

Inconel 625 fasteners

Alloy 625 a le pese awọn boluti, Awọn eso ati awọn ohun elo miiran bi awọn ibeere alabara

Inconel 625 Awọn ẹya:

1.High ti nrakò-rupture agbara

2.Oxidation sooro si 1800 ° F

3.Good rirẹ resistance

4.Excellent weldability

5.Outstanding resistance to kiloraidi pitting ati crevice ipata

6.Immune to kiloraidi ion wahala ipata wo inu

7.Resistant si omi okun labẹ awọn mejeeji ti nṣàn ati ipo ti o duro ati labẹ fifọ

Inconel 625 Aaye ohun elo:

•Ofurufu ducting awọn ọna šiše

•Jet engine eefi awọn ọna šiše

•Awọn ọna ẹrọ ifasilẹ-iyipada

•Bellows ati imugboroosi isẹpo

•Turbine shroud oruka

•Awọn akopọ igbunaya

•Seawater irinše

•Ohun elo ilana ilana kemikali mimu awọn acids adalu mejeeji oxidizing ati idinku.

Awọn fọọmu Awọn ọja ile-iṣẹ wa

Ifi & Awọn ọpa

Inconel / Hastelloy / Monel / Haynes 25/ Titanium

Ailokun Tube & Welded Tube

Awọn tubes nickel / Titanium Alloy, U-tẹ / tube paṣipaarọ ooru

Bolt & Eso

Inconel 601/ Hastelloy C22/Inconel x750/Inconel 625 ect

Dì & Awo

Hastelloy / Inconel / Incoloy / koluboti / Tianium

Rinhoho & bankanje

Hastelloy/Inconel/ invar/ asọ Alloys oofa ect

Ga otutu Springs

Inconel 718 / Inconel x750 / Nimonic 80A

Waya & Alurinmorin

Koluboti Alloy waya, Nickel alloy waya,Tianium Alloy waya

Special Alloy Flanges

Monel 400 / Hastelloy C276 / Inconel 718 / Titanium

Epo Tube Hanger

Inconel x750/ Inconel 718 / Monel 400 ect

Nickel orisun Alloys

Awọn ohun elo alurinmorin

Koluboti Da Alloys

Pataki Irin alagbara

konge Alloys

Titanium Alloys

Ṣe o fẹ kọ ẹkọ diẹ sii tabi gba agbasọ kan?

Wọle Fọwọkan

Ohun elo wo ni 625 alloy ṣe?A nickel – alloy orisun pẹlu Ni – Cr – Mo ga.

Kemikali tiwqn ti Alloy 625: Chromium (Cr) 20.0-23.0, Iron (Fe)< 5.0, (Al) & LT;0.4, Silikoni (Si)< 0.50 manganese (Mn)< 0.50, Nickel (Ni) 258, sulfur (S)< 0.015, Cobalt (Co)< 1.0, (Mo) 8.0-10.0, Titanium (Ti)< 0.4, Phosphorus (P) <0.015, (Nb) 3.15-4.15, Erogba (C) <0.01.

625 Alloy ṣe ẹya ifoyina ti o dara julọ ati idena ipata, agbara ti o dara julọ ati lile, resistance rirẹ ti o dara julọ, fọọmu giga, ati weldability ti o dara julọ.O le ṣetọju agbara ati lile nibikibi lati awọn iwọn otutu kekere si 2000°F.Nitori iyara lile ti alloy 625, iye nla ti dida tutu le nilo annealing jakejado ilana dida tutu.Awọn alloy jẹ igbagbogbo lo ninu awọn ẹrọ oko ofurufu ati awọn ohun elo aerospace miiran.